text.skipToContent

text.skipToNavigation

![KKO]()

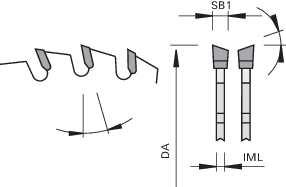

KKO

ID

58808802

Product variants

Product variants

| DA | SB1 | IML | IMD | Zahnzahl | ZK | NL | Achswinkel | Spanwinkel | Eckwinkel | cuttingMaterial1 | Mat.-No. |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 160 | 3.5 | 2.5 | 22 | 36 | WS | 5 | -5 | 15 | HW | 188662 | |

| 160 | 3 | 2.5 | 22 | 36 | WS | 0 | -5 | 15 | HW | 192456 | |

| 90 | 3 | 2 | 30 | 20 | WS | 0 | 8 | 10 | HW | 192471 | |

| 100 | 2.4 | 1.6 | 22 | 12 | WS | 5 | 15 | 10 | HW | 192472 | |

| 100 | 3.2 | 2.2 | 22 | 20 | WS | 0 | 8 | 15 | HW | 192475 | |

| 100 | 2.6 | 1.6 | 32 | 30 | WS | 5 | 10 | 15 | HW | 192476 | |

| 110 | 3.6 | 2.5 | 22 | 20 | WS | 5 | 8 | 30 | HW | 192477 | |

| 110 | 3.6 | 2.5 | 32 | 20 | WS | 5 | 8 | 30 | HW | 192478 | |

| 120 | 3.2 | 2.2 | 32 | 20 | WS | 5 | 10 | 10 | HW | 192483 | |

| 140 | 3.2 | 2.2 | 22 | 36 | WS | 5 | 10 | 15 | HW | 192488 | |

| 140 | 3.2 | 2.2 | 16 | 36 | WS | 5 | 10 | 15 | HW | 192489 | |

| 150 | 3.2 | 2.2 | 22 | 48 | WS | 5 | 10 | 10 | HW | 192493 | |

| 160 | 3.2 | 2.2 | 30 | 24 | WS | 2/7/42 | 5 | 15 | 10 | HW | 192495 |

| 160 | 3.2 | 2.2 | 40 | 30 | WS | 4/5,5/52 | 10 | -8 | 20 | HW | 192496 |

| 160 | 3.2 | 2.2 | 20 | 48 | WS | 2/5/32 | 5 | 10 | 10 | HW | 192497 |

| 160 | 3.2 | 2.2 | 22 | 48 | WS | 5 | -8 | 10 | HW | 192498 | |

| 200 | 3.2 | 2.2 | 30 | 64 | WS | 4/6,6/60 + 2/6,2/42 | 0 | 10 | 15 | HW | 192501 |

| 125 | 2.4 | 1.6 | 32 | 24 | WS | 0 | 15 | 30 | HW | 192900 | |

| 170 | 3.2 | 2.2 | 30 | 36 | WS | 4/5.5/52 | 0 | 10 | 20 | HW | 193354 |

| 100 | 2.4 | 1.6 | 22 | 20 | WS | 2/4/30 | 5 | -8 | 10 | HW | 58808802 |

| DA | SB1 | IML | IMD | Zahnzahl | ZK | NL | Achswinkel | Spanwinkel | Eckwinkel | cuttingMaterial1 | Mat.-No. |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 160 | 3.5 | 2.5 | 22 | 36 | WS | 5 | -5 | 15 | HW | 188662 | |

| 160 | 3 | 2.5 | 22 | 36 | WS | 0 | -5 | 15 | HW | 192456 | |

| 90 | 3 | 2 | 30 | 20 | WS | 0 | 8 | 10 | HW | 192471 | |

| 100 | 2.4 | 1.6 | 22 | 12 | WS | 5 | 15 | 10 | HW | 192472 | |

| 100 | 3.2 | 2.2 | 22 | 20 | WS | 0 | 8 | 15 | HW | 192475 | |

| 100 | 2.6 | 1.6 | 32 | 30 | WS | 5 | 10 | 15 | HW | 192476 | |

| 110 | 3.6 | 2.5 | 22 | 20 | WS | 5 | 8 | 30 | HW | 192477 | |

| 110 | 3.6 | 2.5 | 32 | 20 | WS | 5 | 8 | 30 | HW | 192478 | |

| 120 | 3.2 | 2.2 | 32 | 20 | WS | 5 | 10 | 10 | HW | 192483 | |

| 140 | 3.2 | 2.2 | 22 | 36 | WS | 5 | 10 | 15 | HW | 192488 | |

| 140 | 3.2 | 2.2 | 16 | 36 | WS | 5 | 10 | 15 | HW | 192489 | |

| 150 | 3.2 | 2.2 | 22 | 48 | WS | 5 | 10 | 10 | HW | 192493 | |

| 160 | 3.2 | 2.2 | 30 | 24 | WS | 2/7/42 | 5 | 15 | 10 | HW | 192495 |

| 160 | 3.2 | 2.2 | 40 | 30 | WS | 4/5,5/52 | 10 | -8 | 20 | HW | 192496 |

| 160 | 3.2 | 2.2 | 20 | 48 | WS | 2/5/32 | 5 | 10 | 10 | HW | 192497 |

| 160 | 3.2 | 2.2 | 22 | 48 | WS | 5 | -8 | 10 | HW | 192498 | |

| 200 | 3.2 | 2.2 | 30 | 64 | WS | 4/6,6/60 + 2/6,2/42 | 0 | 10 | 15 | HW | 192501 |

| 125 | 2.4 | 1.6 | 32 | 24 | WS | 0 | 15 | 30 | HW | 192900 | |

| 170 | 3.2 | 2.2 | 30 | 36 | WS | 4/5.5/52 | 0 | 10 | 20 | HW | 193354 |

| 100 | 2.4 | 1.6 | 22 | 20 | WS | 2/4/30 | 5 | -8 | 10 | HW | 58808802 |

Product Details

Maschine

edge banders

edge trimming machines

edge trimming machines

Application

for trimming of plastic-, veneer- and solid wood edges

Design

special NoNoise gullet geometry

positive or negative hook angle

with or without shear angle

tooth configuration: alternate top bevel "WS"

cutting material: HW TC06

Advantages

especially low noise level

noise reduction by approx. 6 dB(A) when idling

noise reduction by approx. 6 dB(A) when idling

Diameter - Outermost cutting point

100

Cutting width 1

2.4

Clamping length

1.6

Bore / shank diameter

22

Number of teeth

20

Tooth configuration

Alternate top bevel

Pin holes

2/4/30

RPM max

018000

Cutting direction

universal

Cutting quality

++

Cutting material group

Hardmetal

Cutting material specification [CMSS1]

Board06

Machine group

Through-feed machines

Machine type

Homag

Machine / Aggregate

Misc. clipping and miter saws

Workpiece material

Plastics

Solidwoodandsolidwoodproducts

Solidwoodandsolidwoodproducts

Workpiece type

Thermoplastics

Thermosetting plastics

Soft wood

Hard wood

Glued laminated timber

Thermosetting plastics

Soft wood

Hard wood

Glued laminated timber

Workpiece material

ABS (block material)

PE (block material)

PP (polypropylene)

PVC (block material)

HPL laminate

Cross cut dry

Veneered timber

Cross cut try hardwood

PE (block material)

PP (polypropylene)

PVC (block material)

HPL laminate

Cross cut dry

Veneered timber

Cross cut try hardwood