text.skipToContent

text.skipToNavigation

![521-1]()

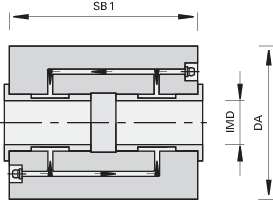

521-1 Hydro Profile Cutterheads

ID

58562927

Product variants

Product variants

| DA | SB1 | IMD | Zahnzahl | Mat.-No. |

|---|---|---|---|---|

| 137 | 60 | 40 | 4 | 58562920 |

| 137 | 100 | 40 | 4 | 58562921 |

| 137 | 130 | 40 | 4 | 58562922 |

| 137 | 150 | 40 | 4 | 58562923 |

| 137 | 180 | 40 | 4 | 58562924 |

| 137 | 230 | 40 | 4 | 58562925 |

| 150 | 60 | 50 | 4 | 58562926 |

| 150 | 100 | 50 | 4 | 58562927 |

| 150 | 130 | 50 | 4 | 58562928 |

| 150 | 150 | 50 | 4 | 58562929 |

| 150 | 180 | 50 | 4 | 58562930 |

| 150 | 230 | 50 | 4 | 58562931 |

| 150 | 260 | 50 | 4 | 58562932 |

| 150 | 310 | 50 | 4 | 58562933 |

| 150 | 60 | 50 | 6 | 58562934 |

| 150 | 100 | 50 | 6 | 58562935 |

| 150 | 130 | 50 | 6 | 58562936 |

| 150 | 150 | 50 | 6 | 58562937 |

| 150 | 180 | 50 | 6 | 58562938 |

| 150 | 230 | 50 | 6 | 58562939 |

| 150 | 260 | 50 | 6 | 58562940 |

| 150 | 310 | 50 | 6 | 58562941 |

| 163 | 60 | 50 | 8 | 58562942 |

| 163 | 100 | 50 | 8 | 58562943 |

| 163 | 130 | 50 | 8 | 58562944 |

| 163 | 150 | 50 | 8 | 58562945 |

| 163 | 180 | 50 | 8 | 58562946 |

| 163 | 230 | 50 | 8 | 58562947 |

| 163 | 260 | 50 | 8 | 58562948 |

| 163 | 310 | 50 | 8 | 58562949 |

| DA | SB1 | IMD | Zahnzahl | Mat.-No. |

|---|---|---|---|---|

| 137 | 60 | 40 | 4 | 58562920 |

| 137 | 100 | 40 | 4 | 58562921 |

| 137 | 130 | 40 | 4 | 58562922 |

| 137 | 150 | 40 | 4 | 58562923 |

| 137 | 180 | 40 | 4 | 58562924 |

| 137 | 230 | 40 | 4 | 58562925 |

| 150 | 60 | 50 | 4 | 58562926 |

| 150 | 100 | 50 | 4 | 58562927 |

| 150 | 130 | 50 | 4 | 58562928 |

| 150 | 150 | 50 | 4 | 58562929 |

| 150 | 180 | 50 | 4 | 58562930 |

| 150 | 230 | 50 | 4 | 58562931 |

| 150 | 260 | 50 | 4 | 58562932 |

| 150 | 310 | 50 | 4 | 58562933 |

| 150 | 60 | 50 | 6 | 58562934 |

| 150 | 100 | 50 | 6 | 58562935 |

| 150 | 130 | 50 | 6 | 58562936 |

| 150 | 150 | 50 | 6 | 58562937 |

| 150 | 180 | 50 | 6 | 58562938 |

| 150 | 230 | 50 | 6 | 58562939 |

| 150 | 260 | 50 | 6 | 58562940 |

| 150 | 310 | 50 | 6 | 58562941 |

| 163 | 60 | 50 | 8 | 58562942 |

| 163 | 100 | 50 | 8 | 58562943 |

| 163 | 130 | 50 | 8 | 58562944 |

| 163 | 150 | 50 | 8 | 58562945 |

| 163 | 180 | 50 | 8 | 58562946 |

| 163 | 230 | 50 | 8 | 58562947 |

| 163 | 260 | 50 | 8 | 58562948 |

| 163 | 310 | 50 | 8 | 58562949 |

Product Details

Maschine

hydro profile molders

Application

for profiling of solid woods

Design

body made from steel

Advantages

best cutting quality without knife marks at high feed rates

precise concentricity tolerance (system Weinig) thanks to dual-chamber Hydro clamping

high concentric accuracy and low operating vibration

tight clamping thanks to precise serration (60 degrees, 1.6 mm pitch)

precise concentricity tolerance (system Weinig) thanks to dual-chamber Hydro clamping

high concentric accuracy and low operating vibration

tight clamping thanks to precise serration (60 degrees, 1.6 mm pitch)

Notes

adjustable knives

profile depth and cutting circle diameter see table

for back-serrated blanks S = 5, 8, 10 mm

included in delivery: cutterhead with clamping bar

Diameter - Outermost cutting point

150

Diameter max

150

Cutting width 1

100

Bore / shank diameter

50

Number of teeth

4

RPM max

006000

Cutting direction

universal

Type of feed

MEC - mechanical feed

Machine group

Molders

Machine type

Molder planing

Machine / Aggregate

Misc. Molder planing machine

Scope of application

Machining of solid wood

Application

saw mills / planing mills

Processing step

Planing/Profiling

Workpiece material

Solidwoodandsolidwoodproducts

Workpiece type

Soft wood

Hard wood

Glued laminated timber

Hard wood

Glued laminated timber

Workpiece material

Longitudinal cut wet softwood

Longitudinal cut dry

Cross cut wet

Cross cut dry

BSH

Veneered timber

KVH

Glued laminated timber board

Longitudinal cut wet hardwood

Longitudinal cut dry hardwood

Cross cut wet hardwood

Cross cut try hardwood

Longitudinal cut dry

Cross cut wet

Cross cut dry

BSH

Veneered timber

KVH

Glued laminated timber board

Longitudinal cut wet hardwood

Longitudinal cut dry hardwood

Cross cut wet hardwood

Cross cut try hardwood