text.skipToContent

text.skipToNavigation

![C2-112-n-g-LEUCO]()

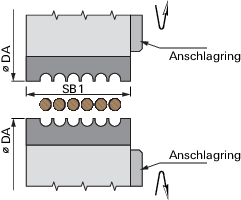

464 Multi Dowel Cutterheads

ID

50389274

Product variants

Product variants

| DA | SB1 | IMD | IMDmax | Zahnzahl | nMax | cuttingMaterial1 | Mat.-No. |

|---|---|---|---|---|---|---|---|

| 102 | 50 | 35 | 40 | 2 | 006000 | HS | 50389261 |

| 102 | 75 | 35 | 40 | 2 | 006000 | HS | 50389262 |

| 102 | 100 | 35 | 40 | 2 | 006000 | HS | 50389263 |

| 102 | 50 | 40 | 40 | 2 | 006000 | HS | 50389264 |

| 102 | 75 | 40 | 40 | 2 | 006000 | HS | 50389265 |

| 102 | 100 | 40 | 40 | 2 | 006000 | HS | 50389266 |

| 102 | 125 | 40 | 40 | 2 | 006000 | HS | 50389267 |

| 102 | 150 | 40 | 40 | 4 | 006000 | HS | 50389268 |

| 102 | 50 | 35 | 40 | 4 | 006000 | HS | 50389269 |

| 102 | 75 | 35 | 40 | 4 | 006000 | HS | 50389270 |

| 102 | 100 | 35 | 40 | 4 | 006000 | HS | 50389271 |

| 102 | 50 | 40 | 40 | 4 | 006000 | HS | 50389272 |

| 102 | 75 | 40 | 40 | 4 | 006000 | HS | 50389273 |

| 102 | 100 | 40 | 40 | 4 | 006000 | HS | 50389274 |

| 102 | 125 | 40 | 40 | 4 | 006000 | HS | 50389275 |

| 102 | 150 | 40 | 40 | 4 | 006000 | HS | 50389276 |

| DA | SB1 | IMD | IMDmax | Zahnzahl | nMax | cuttingMaterial1 | Mat.-No. |

|---|---|---|---|---|---|---|---|

| 102 | 50 | 35 | 40 | 2 | 006000 | HS | 50389261 |

| 102 | 75 | 35 | 40 | 2 | 006000 | HS | 50389262 |

| 102 | 100 | 35 | 40 | 2 | 006000 | HS | 50389263 |

| 102 | 50 | 40 | 40 | 2 | 006000 | HS | 50389264 |

| 102 | 75 | 40 | 40 | 2 | 006000 | HS | 50389265 |

| 102 | 100 | 40 | 40 | 2 | 006000 | HS | 50389266 |

| 102 | 125 | 40 | 40 | 2 | 006000 | HS | 50389267 |

| 102 | 150 | 40 | 40 | 4 | 006000 | HS | 50389268 |

| 102 | 50 | 35 | 40 | 4 | 006000 | HS | 50389269 |

| 102 | 75 | 35 | 40 | 4 | 006000 | HS | 50389270 |

| 102 | 100 | 35 | 40 | 4 | 006000 | HS | 50389271 |

| 102 | 50 | 40 | 40 | 4 | 006000 | HS | 50389272 |

| 102 | 75 | 40 | 40 | 4 | 006000 | HS | 50389273 |

| 102 | 100 | 40 | 40 | 4 | 006000 | HS | 50389274 |

| 102 | 125 | 40 | 40 | 4 | 006000 | HS | 50389275 |

| 102 | 150 | 40 | 40 | 4 | 006000 | HS | 50389276 |

Product Details

Maschine

multi spindle milling machines

Application

for the production of smooth round bars of 2 to 16 mm and of corrugated dowels of 6.1 to 16.1 mm in solid woods

Design

body made from steel

2 or 4 knife holders

Advantages

quick knife change

self-centering knife seat

self-centering knife seat

Notes

guide-plate for axial adjustment of knives

further profiles on request

Diameter - Outermost cutting point

102

Diameter max

102

Cutting width 1

100

Bore / shank diameter

40

Number of teeth

4

RPM max

006000

Cutting direction

universal

Type of feed

MEC - mechanical feed

Cutting material group

High speed steel (HSS)

Machine group

Through-feed machines

Molders

Molders

Machine type

Universell

Homag

Molder profiling

Homag

Molder profiling

Machine / Aggregate

Homag Doppelendprofiler - Präz

Misc. Molder profiling machine

Misc. Molder profiling machine

Scope of application

Machining of solid wood

through-feed processing

through-feed processing

Application

saw mills / planing mills

Furniture manufacturing

Edge trimming refinishing

Furniture manufacturing

Edge trimming refinishing

Processing step

Planing/Profiling furniture

Profile cutting

Planing/Profiling

Profile cutting

Planing/Profiling

Workpiece material

Solidwoodandsolidwoodproducts

Workpiece type

Soft wood

Hard wood

Glued laminated timber

Hard wood

Glued laminated timber

Workpiece material

Longitudinal cut wet softwood

Longitudinal cut dry

Cross cut wet

Cross cut dry

BSH

Veneered timber

KVH

Glued laminated timber board

Longitudinal cut wet hardwood

Longitudinal cut dry hardwood

Cross cut wet hardwood

Cross cut try hardwood

Longitudinal cut dry

Cross cut wet

Cross cut dry

BSH

Veneered timber

KVH

Glued laminated timber board

Longitudinal cut wet hardwood

Longitudinal cut dry hardwood

Cross cut wet hardwood

Cross cut try hardwood