text.skipToContent

text.skipToNavigation

![4000-1-LEUCO]()

4000 Tongue and Groove Tools

ID

58532387

Product variants

Product variants

| DA | SB1 | SBmin1 | SBmax1 | IMD | Zahnzahl | TYPE | nMax | WTmax | WTmin | cuttingMaterial1 | Mat.-No. |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 180 | 35 | 4.5 | 7.5 | 40 | 6 | 501/502 | 008000 | 36 | 12 | HS | 58532354 |

| 180 | 35 | 4.5 | 7.5 | 40 | 6 | 505/506 | 008000 | 27 | 15 | HS | 58532358 |

| 180 | 35 | 4.5 | 7.5 | 40 | 6+3 | 512/513 | 008000 | 27 | 12 | HS | 58532361 |

| 180 | 35 | 4.5 | 7.5 | 40 | 6 | 503/502 | 008000 | 36 | 12 | HS | 58532382 |

| 180 | 35 | 4.5 | 7.5 | 40 | 6 | 529/530 | 008000 | 27 | 15 | HS | 58532384 |

| 180 | 35 | 4.5 | 7.5 | 40 | 6 | 507/508 | 008000 | 27 | 15 | HS | 58532387 |

| 180 | 35 | 4.5 | 7.5 | 40 | 6+3 | 525/526 | 008000 | 27 | 12 | HS | 58532390 |

| 180 | 35 | 4.5 | 7.5 | 40 | 6+3 | 541/540 | 008000 | 19 | 14 | HS | 58532391 |

| DA | SB1 | SBmin1 | SBmax1 | IMD | Zahnzahl | TYPE | nMax | WTmax | WTmin | cuttingMaterial1 | Mat.-No. |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 180 | 35 | 4.5 | 7.5 | 40 | 6 | 501/502 | 008000 | 36 | 12 | HS | 58532354 |

| 180 | 35 | 4.5 | 7.5 | 40 | 6 | 505/506 | 008000 | 27 | 15 | HS | 58532358 |

| 180 | 35 | 4.5 | 7.5 | 40 | 6+3 | 512/513 | 008000 | 27 | 12 | HS | 58532361 |

| 180 | 35 | 4.5 | 7.5 | 40 | 6 | 503/502 | 008000 | 36 | 12 | HS | 58532382 |

| 180 | 35 | 4.5 | 7.5 | 40 | 6 | 529/530 | 008000 | 27 | 15 | HS | 58532384 |

| 180 | 35 | 4.5 | 7.5 | 40 | 6 | 507/508 | 008000 | 27 | 15 | HS | 58532387 |

| 180 | 35 | 4.5 | 7.5 | 40 | 6+3 | 525/526 | 008000 | 27 | 12 | HS | 58532390 |

| 180 | 35 | 4.5 | 7.5 | 40 | 6+3 | 541/540 | 008000 | 19 | 14 | HS | 58532391 |

Product Details

Maschine

molders

double end tenoners

double end tenoners

Application

for tongue and groove board with or without space allowance in material (=open joint) or chamfer in soft and hard woods

Design

body made from steel

adjustable by means of spacers

highest precision thanks to plane parallelism of all parts

secured against rotation by means of 3 driving pins on minor diameter 75 mm

Notes

indicate sense of rotation, direction of feed and face side according to diagram I, II, III or IV when placing an order

without indications we will deliver according to diagram I

delivery with HW-tipping possible with surcharge

Diameter - Outermost cutting point

180

Diameter max

180

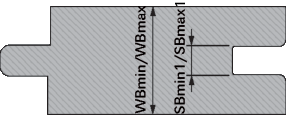

Cutting width 1

35

Cutting width 1 min

4.5

Cutting width 1 max

7.5

Bore / shank diameter

40

Number of teeth

6

RPM max

008000

Cutting direction

universal

Type of feed

MEC - mechanical feed

Cutting material group

High speed steel (HSS)

Machine group

Molders

Through-feed machines

Through-feed machines

Machine type

Molder profiling

Molder planing

Molder groove bed

Homag

Molder planing

Molder groove bed

Homag

Machine / Aggregate

Misc. Molder profiling machine

Homag Doppelendprofiler - Präz

Misc. Molder planing machine

Misc. Molder groovebed machine

Homag Doppelendprofiler - Präz

Misc. Molder planing machine

Misc. Molder groovebed machine

Scope of application

Machining of solid wood

through-feed processing

through-feed processing

Application

saw mills / planing mills

Furniture manufacturing

Edge trimming refinishing

Furniture manufacturing

Edge trimming refinishing

Processing step

Planing/Profiling furniture

Profile cutting

Planing/Profiling

Profile cutting

Planing/Profiling

Workpiece material

Solidwoodandsolidwoodproducts

Workpiece type

Soft wood

Hard wood

Glued laminated timber

Hard wood

Glued laminated timber

Workpiece material

Longitudinal cut wet hardwood

Longitudinal cut dry

Cross cut dry

BSH

Veneered timber

KVH

Glued laminated timber board

Longitudinal cut dry hardwood

Cross cut try hardwood

Longitudinal cut dry

Cross cut dry

BSH

Veneered timber

KVH

Glued laminated timber board

Longitudinal cut dry hardwood

Cross cut try hardwood