text.skipToContent

text.skipToNavigation

![188369]()

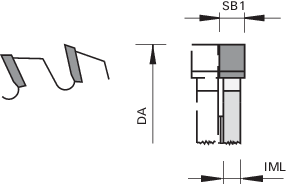

1101 Grooving Saw Blade

ID

188370

Product variants

Product variants

Product Details

Maschine

table shapers

Application

for chip-free grooving in solid woods and in wood-based panels

Design

tooth configuration: flat "F"

cutting material: HW

cutting material: HW

Notes

application against feed with the grain (solid wood)

application with feed only with MEC (wood-based panels)

other grooving widths possible by set-combinations

groove width calculation for tool sets: sum of all "b" + HW overlap left and right + shim thickness

Diameter - Outermost cutting point

125

Diameter max

125

Cutting width 1

7

Interface towards the machine

Bore

Bore / shank diameter

30

Number of teeth

12

RPM min

006100

RPM max

010700

Cutting direction

universal

Type of feed

MAN - manual feed

Cutting material group

Hardmetal

Machine group

Milling centers

Machine type

CNC stationary manufacturing

Table shaper

Table shaper

Machine / Aggregate

Format 4 Table shaper

Panhans Table shaper

SCM Table shaper

Altendorf Table shaper

Bäuerle Table shaper

Felder Table shaper

Hokubema Table shaper

Koelle Table shaper

Lohmeyer Table shaper

Martin Table shaper

Panhans Table shaper

SCM Table shaper

Altendorf Table shaper

Bäuerle Table shaper

Felder Table shaper

Hokubema Table shaper

Koelle Table shaper

Lohmeyer Table shaper

Martin Table shaper

Scope of application

CNC machining

Application

Furniture manufacturing

Processing step

Planing/Profiling furniture

Workpiece material

Wood composite materials

Wood-based panels

Solidwoodandsolidwoodproducts

Wood-based panels

Solidwoodandsolidwoodproducts

Workpiece type

Lightweight panel

Solid wood and veneered mat

Particle boards

Laminated particle board

MDF

HDF

Soft wood

Hard wood

Glued laminated timber

Solid wood and veneered mat

Particle boards

Laminated particle board

MDF

HDF

Soft wood

Hard wood

Glued laminated timber

Workpiece material

MDF-Polystyrene panel

Blockboard

Honeycomb panel

Plywood

Multiplex

Wood core plywood

OSB particle board flooring

Particle board (raw)

Particle board (CPL-coated)

Particle board (veneered)

Particleboard-highglossfoiled

Spanplatte (HPL beschichtet)

Particle board-melamcoverlay

Twin-wall panel

MDF (raw)

MDF (lacquered)

MDF profiles (coated)

MDF (high gloss lacquered)

HDF (panel material)

Longitudinal cut dry

Cross cut dry

BSH

Veneered timber

KVH

Glued laminated timber board

Longitudinal cut dry hardwood

Cross cut try hardwood

Blockboard

Honeycomb panel

Plywood

Multiplex

Wood core plywood

OSB particle board flooring

Particle board (raw)

Particle board (CPL-coated)

Particle board (veneered)

Particleboard-highglossfoiled

Spanplatte (HPL beschichtet)

Particle board-melamcoverlay

Twin-wall panel

MDF (raw)

MDF (lacquered)

MDF profiles (coated)

MDF (high gloss lacquered)

HDF (panel material)

Longitudinal cut dry

Cross cut dry

BSH

Veneered timber

KVH

Glued laminated timber board

Longitudinal cut dry hardwood

Cross cut try hardwood