text.skipToContent

text.skipToNavigation

![Steel]()

Steel

ID

58805861

Product variants

Product variants

| DA | SB1 | IML | IMD | Zahnzahl | ZK | NL | Spanwinkel | cuttingMaterial1 | Mat.-No. |

|---|---|---|---|---|---|---|---|---|---|

| 320 | 2.2 | 1.8 | 25.4 | 84 | F-WFA | 0 | HW | 58805859 | |

| 254 | 2.2 | 1.8 | 30 | 60 | F-WFA | 2/7/42 + 2/9,5/46,5 + 2/10/60 | 0 | HW | 58805861 |

| 305 | 2.2 | 1.8 | 25.4 | 60 | F-WFA | 0 | HW | 58805862 | |

| 305 | 2.2 | 1.8 | 25.4 | 80 | F-WFA | 0 | HW | 58805863 | |

| 305 | 2.2 | 1.8 | 30 | 80 | F-WFA | 2/7/42 + 2/9,5/46,5 + 2/10/60 | 10 | HW | 58805864 |

| 330 | 2.2 | 1.8 | 30 | 90 | F-WFA | 2/7/42 + 2/9,5/46,5 + 2/10/60 | 0 | HW | 58805865 |

| 355 | 2.2 | 1.8 | 25.4 | 80 | F-WFA | 0 | HW | 58805866 | |

| 355 | 2.2 | 1.8 | 30 | 90 | F-WFA | 2/7/42 + 2/9,5/46,5 + 2/10/60 | 0 | HW | 58805867 |

| 355 | 2.2 | 1.8 | 25.4 | 90 | F-WFA | 0 | HW | 58805868 |

| DA | SB1 | IML | IMD | Zahnzahl | ZK | NL | Spanwinkel | cuttingMaterial1 | Mat.-No. |

|---|---|---|---|---|---|---|---|---|---|

| 320 | 2.2 | 1.8 | 25.4 | 84 | F-WFA | 0 | HW | 58805859 | |

| 254 | 2.2 | 1.8 | 30 | 60 | F-WFA | 2/7/42 + 2/9,5/46,5 + 2/10/60 | 0 | HW | 58805861 |

| 305 | 2.2 | 1.8 | 25.4 | 60 | F-WFA | 0 | HW | 58805862 | |

| 305 | 2.2 | 1.8 | 25.4 | 80 | F-WFA | 0 | HW | 58805863 | |

| 305 | 2.2 | 1.8 | 30 | 80 | F-WFA | 2/7/42 + 2/9,5/46,5 + 2/10/60 | 10 | HW | 58805864 |

| 330 | 2.2 | 1.8 | 30 | 90 | F-WFA | 2/7/42 + 2/9,5/46,5 + 2/10/60 | 0 | HW | 58805865 |

| 355 | 2.2 | 1.8 | 25.4 | 80 | F-WFA | 0 | HW | 58805866 | |

| 355 | 2.2 | 1.8 | 30 | 90 | F-WFA | 2/7/42 + 2/9,5/46,5 + 2/10/60 | 0 | HW | 58805867 |

| 355 | 2.2 | 1.8 | 25.4 | 90 | F-WFA | 0 | HW | 58805868 |

Product Details

Maschine

dry-cut machines

universal metal-cut machines

universal metal-cut machines

Application

for dividing and miter cuts in composite materials, metal sheets, plastics, NF-metals, cable ducts, profiles, SML-tubes, etc.

Design

tooth configuration: flat with alternating chamfer "F-WFA"

cutting material: HW TCm13

cutting material: HW TCm13

Advantages

dry cut

excellent cutting qualtiy

excellent cutting qualtiy

Notes

recommended RPM:

Ø254 = 1750 min-1

Ø305 = 1500 min-1

Ø330 = 1350 min-1

Ø355 = 1250 min-1

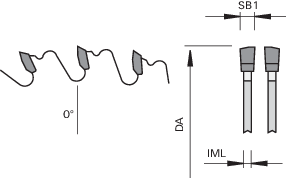

Diameter - Outermost cutting point

254

Cutting width 1

2.2

Clamping length

1.8

Bore / shank diameter

30

Number of teeth

60

Tooth configuration

Flachzahn mit wechselseitiger Fase

Pin holes

2/7/42 + 2/9,5/46,5 + 2/10/60

RPM max

007600

Cutting direction

universal

Cutting quality

++

Cutting material group

Hardmetal

Cutting material specification [CMSS1]

Steel13

Machine group

sawing machines

Workpiece material

Metals

Workpiece type

Composite material

Aluminum

Copper

Aluminum

Copper

Workpiece material

Aluminum (sheet)

Aluminum (hollow profile)

Aluminum (foam)

Aluminum (block material)

Aluminum (honeycomb panel)

Copper (sheet)

Aluminium-HPL

Aluminum polyethylene

AlusandwichboardwithPufilling

Aluminum plywood

Aluminum composite materials

Iron covered particle board

Steelplasticacousticelements

Steel laminated timber

Aluminum (hollow profile)

Aluminum (foam)

Aluminum (block material)

Aluminum (honeycomb panel)

Copper (sheet)

Aluminium-HPL

Aluminum polyethylene

AlusandwichboardwithPufilling

Aluminum plywood

Aluminum composite materials

Iron covered particle board

Steelplasticacousticelements

Steel laminated timber