text.skipToContent

text.skipToNavigation

![173797]()

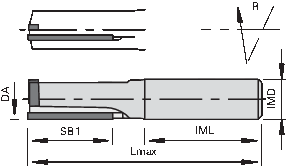

3501 Shank-Type Cutters

ID

181104

Product variants

Product variants

| DA | SB1 | IML | IMD | Lmax | Zahnzahl | nMax | DR1 | resharpeningZone | cuttingMaterial1 | Mat.-No. |

|---|---|---|---|---|---|---|---|---|---|---|

| 8 | 12 | 35 | 12 | 60 | 2 | 024000 | RH | 0.5 | DP | 178659 |

| 12 | 25.4 | 35 | 12 | 70 | 1 | 024000 | RH | 1.5 | DP | 181102 |

| 16 | 25.4 | 45 | 16 | 85 | 1 | 024000 | RH | 1.2 | DP | 181104 |

| 16 | 35 | 45 | 16 | 95 | 1 | 024000 | RH | 1.2 | DP | 181106 |

| 6 | 12 | 40 | 12 | 70 | 1 | 024000 | RH | 0.2 | DP | 183567 |

| 10 | 22 | 35 | 12 | 70 | 2 | 024000 | RH | 1.2 | DP | 186784 |

| 10 | 22 | 35 | 12 | 70 | 2 | 024000 | LH | 1.2 | DP | 186785 |

| 8 | 22 | 35 | 12 | 70 | 2 | 024000 | RH | 0.5 | DP | 187724 |

| DA | SB1 | IML | IMD | Lmax | Zahnzahl | nMax | DR1 | resharpeningZone | cuttingMaterial1 | Mat.-No. |

|---|---|---|---|---|---|---|---|---|---|---|

| 8 | 12 | 35 | 12 | 60 | 2 | 024000 | RH | 0.5 | DP | 178659 |

| 12 | 25.4 | 35 | 12 | 70 | 1 | 024000 | RH | 1.5 | DP | 181102 |

| 16 | 25.4 | 45 | 16 | 85 | 1 | 024000 | RH | 1.2 | DP | 181104 |

| 16 | 35 | 45 | 16 | 95 | 1 | 024000 | RH | 1.2 | DP | 181106 |

| 6 | 12 | 40 | 12 | 70 | 1 | 024000 | RH | 0.2 | DP | 183567 |

| 10 | 22 | 35 | 12 | 70 | 2 | 024000 | RH | 1.2 | DP | 186784 |

| 10 | 22 | 35 | 12 | 70 | 2 | 024000 | LH | 1.2 | DP | 186785 |

| 8 | 22 | 35 | 12 | 70 | 2 | 024000 | RH | 0.5 | DP | 187724 |

Product Details

Maschine

CNC routers

Application

for jointing and sizing without overlap marks in wood-based panels, solid woods and plastics

Design

polished face and high-finish clearance angle

with HW plunge tip for diagonal plunge-cutting (travelling plunge-cut using Z and X axis)

straight cutter axis

solid tungsten carbide body for <= Ø 10 mm

with HW plunge tip for diagonal plunge-cutting (travelling plunge-cut using Z and X axis)

straight cutter axis

solid tungsten carbide body for <= Ø 10 mm

Advantages

high quality machining of MDF and hard woods

no overlap-marks thanks to continuous cutting edge

increased stability thanks to special design of brazing area

no overlap-marks thanks to continuous cutting edge

increased stability thanks to special design of brazing area

Notes

clamping elements: ps-System, TRIBOS , draw-in collet chuck

with thread for length adjusting screw

Diameter - Outermost cutting point

16

Cutting width 1

25.4

Interface towards the machine

Shank

Bore / shank diameter

16

Number of teeth

1

RPM max

024000

Cutting direction

right-handed

Total length 1

85

Cutting material group

Diamond, polycrystalline

Machine group

Milling centers

Machine type

CNC stationary manufacturing

Machine / Aggregate

Biesse CNC stationary manuf.

HOLZ-HER CNC stationary manuf.

Alberti

Anderson

CMS

HOMAG CNC stationary manuf.

IMA CNC stationary manuf.

Nanxing CNC stationary manuf.

SCM CNC stationary manuf.

Felder CNC stationary manuf.

Heian

Komo

Maka

Masterwood

Morbidelli CNC stationary manu

Multichem

Reichenbacher Hamuel

Shoda

Weeke CNC stationary manufactu

Weeke BHX 050

Weeke BHX 055

Weeke BHX 500

HOLZ-HER CNC stationary manuf.

Alberti

Anderson

CMS

HOMAG CNC stationary manuf.

IMA CNC stationary manuf.

Nanxing CNC stationary manuf.

SCM CNC stationary manuf.

Felder CNC stationary manuf.

Heian

Komo

Maka

Masterwood

Morbidelli CNC stationary manu

Multichem

Reichenbacher Hamuel

Shoda

Weeke CNC stationary manufactu

Weeke BHX 050

Weeke BHX 055

Weeke BHX 500

Scope of application

CNC machining

Application

Furniture manufacturing

Processing step

Planing/Profiling furniture

Workpiece material

Solidwoodandsolidwoodproducts

special manufacturermaterials

special manufacturermaterials

Workpiece type

Soft wood

obo®

obo®

Workpiece material

Longitudinal cut dry

Cross cut dry

maridur® 30-70

Cross cut dry

maridur® 30-70