text.skipToContent

text.skipToNavigation

![]()

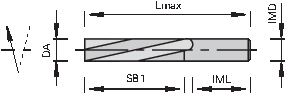

2257 Finishing Cutters

ID

50811421

Product variants

Product variants

| DA | SB1 | IML | IMD | Lmax | Zahnzahl | cuttingMaterial1 | Mat.-No. |

|---|---|---|---|---|---|---|---|

| 6 | 15 | 36 | 6 | 60 | 2 | VHW | 178327 |

| 10 | 30 | 40 | 10 | 75 | 2 | VHW | 178332 |

| 12 | 42 | 45 | 12 | 90 | 2 | VHW | 178335 |

| 12 | 42 | 45 | 12 | 90 | 3 | VHW | 178336 |

| 16 | 35 | 48 | 16 | 90 | 2 | VHW | 178342 |

| 16 | 35 | 48 | 16 | 90 | 3 | VHW | 178343 |

| 16 | 55 | 48 | 16 | 110 | 3 | VHW | 178347 |

| 20 | 55 | 50 | 20 | 115 | 3 | VHW | 178354 |

| 20 | 75 | 50 | 20 | 135 | 3 | VHW | 178356 |

| 4 | 15 | 28 | 4 | 60 | 2 | VHW | 50811418 |

| 8 | 30 | 36 | 8 | 75 | 2 | VHW | 50811421 |

| DA | SB1 | IML | IMD | Lmax | Zahnzahl | cuttingMaterial1 | Mat.-No. |

|---|---|---|---|---|---|---|---|

| 6 | 15 | 36 | 6 | 60 | 2 | VHW | 178327 |

| 10 | 30 | 40 | 10 | 75 | 2 | VHW | 178332 |

| 12 | 42 | 45 | 12 | 90 | 2 | VHW | 178335 |

| 12 | 42 | 45 | 12 | 90 | 3 | VHW | 178336 |

| 16 | 35 | 48 | 16 | 90 | 2 | VHW | 178342 |

| 16 | 35 | 48 | 16 | 90 | 3 | VHW | 178343 |

| 16 | 55 | 48 | 16 | 110 | 3 | VHW | 178347 |

| 20 | 55 | 50 | 20 | 115 | 3 | VHW | 178354 |

| 20 | 75 | 50 | 20 | 135 | 3 | VHW | 178356 |

| 4 | 15 | 28 | 4 | 60 | 2 | VHW | 50811418 |

| 8 | 30 | 36 | 8 | 75 | 2 | VHW | 50811421 |

Product Details

Maschine

CNC routers

Application

for finish cutting in solid woods and plastic

for cutting of cut-outs and contours

traveling plunge cut using Z and X or Y axis

for cutting of cut-outs and contours

traveling plunge cut using Z and X or Y axis

Design

negative spiral for smaller workpieces hard to clamp with face side up

n max = 30,000 min-1

n max = 30,000 min-1

Advantages

cutting pressure and chip evacuation towards the bottom thanks to negative spiral

Notes

clamping elements: ps-System with intermediate sleeves, TRIBOS, draw-in collet chuck

Diameter - Outermost cutting point

8

Cutting width 1

30

Bore / shank diameter

8

Number of teeth

2

RPM max

030000

Cutting direction

right-handed

Cutting material group

Solid Hardmetal

Machine group

Milling centers

Machine type

CNC stationary manufacturing

Machine / Aggregate

Biesse CNC stationary manuf.

HOLZ-HER CNC stationary manuf.

HOMAG CNC stationary manuf.

IMA CNC stationary manuf.

Nanxing CNC stationary manuf.

SCM CNC stationary manuf.

Felder CNC stationary manuf.

Alberti

Anderson

CMS

Heian

Komo

Maka

Masterwood

Morbidelli CNC stationary manu

Multichem

Reichenbacher Hamuel

Shoda

Weeke CNC stationary manufactu

Weeke BHX 050

Weeke BHX 055

Weeke BHX 500

HOLZ-HER CNC stationary manuf.

HOMAG CNC stationary manuf.

IMA CNC stationary manuf.

Nanxing CNC stationary manuf.

SCM CNC stationary manuf.

Felder CNC stationary manuf.

Alberti

Anderson

CMS

Heian

Komo

Maka

Masterwood

Morbidelli CNC stationary manu

Multichem

Reichenbacher Hamuel

Shoda

Weeke CNC stationary manufactu

Weeke BHX 050

Weeke BHX 055

Weeke BHX 500

Workpiece material

Wood-based panels

Solidwoodandsolidwoodproducts

Solidwoodandsolidwoodproducts

Workpiece type

Solid wood and veneered mat

Particle boards

Insulating boards

MDF

HDF

Soft wood

Hard wood

Glued laminated timber

Cork

Particle boards

Insulating boards

MDF

HDF

Soft wood

Hard wood

Glued laminated timber

Cork

Workpiece material

Plywood

Multiplex

Wood core plywood

OSB particle board flooring

Particle board (raw)

Insulatingboardsoftfiberboard

Twin-wall panel

MDF (raw)

MDF (lacquered)

MDF profiles (coated)

HDF (panel material)

Longitudinal cut wet softwood

Longitudinal cut dry

Cross cut wet

Cross cut dry

BSH

Veneered timber

KVH

Glued laminated timber board

Cork

Longitudinal cut wet hardwood

Longitudinal cut dry hardwood

Cross cut wet hardwood

Cross cut try hardwood

Multiplex

Wood core plywood

OSB particle board flooring

Particle board (raw)

Insulatingboardsoftfiberboard

Twin-wall panel

MDF (raw)

MDF (lacquered)

MDF profiles (coated)

HDF (panel material)

Longitudinal cut wet softwood

Longitudinal cut dry

Cross cut wet

Cross cut dry

BSH

Veneered timber

KVH

Glued laminated timber board

Cork

Longitudinal cut wet hardwood

Longitudinal cut dry hardwood

Cross cut wet hardwood

Cross cut try hardwood