text.skipToContent

text.skipToNavigation

![181167]()

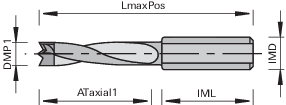

2040 Dowel Bits

ID

50600649

Product variants

Product variants

| DRP1 | ATaxial1 | IML | IMD | Lmax | DR1 | cuttingMaterial1 | Mat.-No. |

|---|---|---|---|---|---|---|---|

| 10 | 25 | 27 | 10 | 57.5 | LH | HW | 181524 |

| 5 | 25 | 27 | 10 | 57.5 | LH | HW | 50600640 |

| 5 | 25 | 27 | 10 | 57.5 | RH | HW | 50600641 |

| 6 | 25 | 27 | 10 | 57.5 | LH | HW | 50600642 |

| 6 | 25 | 27 | 10 | 57.5 | RH | HW | 50600643 |

| 8 | 25 | 27 | 10 | 57.5 | LH | HW | 50600644 |

| 8 | 25 | 27 | 10 | 57.5 | RH | HW | 50600645 |

| 10 | 25 | 27 | 10 | 57.5 | RH | HW | 50600647 |

| 5 | 35 | 30 | 10 | 70 | LH | HW | 50600648 |

| 5 | 35 | 30 | 10 | 70 | RH | HW | 50600649 |

| 6 | 35 | 30 | 10 | 70 | LH | HW | 50600650 |

| 6 | 35 | 30 | 10 | 70 | RH | HW | 50600651 |

| 8 | 35 | 30 | 10 | 70 | LH | HW | 50600652 |

| 8 | 35 | 30 | 10 | 70 | RH | HW | 50600653 |

| 10 | 35 | 30 | 10 | 70 | LH | HW | 50600654 |

| 10 | 35 | 30 | 10 | 70 | RH | HW | 50600655 |

| DRP1 | ATaxial1 | IML | IMD | Lmax | DR1 | cuttingMaterial1 | Mat.-No. |

|---|---|---|---|---|---|---|---|

| 10 | 25 | 27 | 10 | 57.5 | LH | HW | 181524 |

| 5 | 25 | 27 | 10 | 57.5 | LH | HW | 50600640 |

| 5 | 25 | 27 | 10 | 57.5 | RH | HW | 50600641 |

| 6 | 25 | 27 | 10 | 57.5 | LH | HW | 50600642 |

| 6 | 25 | 27 | 10 | 57.5 | RH | HW | 50600643 |

| 8 | 25 | 27 | 10 | 57.5 | LH | HW | 50600644 |

| 8 | 25 | 27 | 10 | 57.5 | RH | HW | 50600645 |

| 10 | 25 | 27 | 10 | 57.5 | RH | HW | 50600647 |

| 5 | 35 | 30 | 10 | 70 | LH | HW | 50600648 |

| 5 | 35 | 30 | 10 | 70 | RH | HW | 50600649 |

| 6 | 35 | 30 | 10 | 70 | LH | HW | 50600650 |

| 6 | 35 | 30 | 10 | 70 | RH | HW | 50600651 |

| 8 | 35 | 30 | 10 | 70 | LH | HW | 50600652 |

| 8 | 35 | 30 | 10 | 70 | RH | HW | 50600653 |

| 10 | 35 | 30 | 10 | 70 | LH | HW | 50600654 |

| 10 | 35 | 30 | 10 | 70 | RH | HW | 50600655 |

Product Details

Maschine

portable boring machines

automatic boring machines

CNC machining centers

automatic boring machines

CNC machining centers

Application

for chip-free drilling of dowel holes in solid woods and wood-based panels

Design

special cutting edge geometry

2 spurs

centering point

HW-tipped

2 spurs

centering point

HW-tipped

Advantages

chip-free hole edges thanks to special cutting edge geometry with spurs

safe drilling thanks to centering point

high process safety thanks to constant quality of the bores for a long time

tool life increased up to sixfold compared to traditional dowel bits thanks to wear-resistant HW plunging tip

safe drilling thanks to centering point

high process safety thanks to constant quality of the bores for a long time

tool life increased up to sixfold compared to traditional dowel bits thanks to wear-resistant HW plunging tip

Notes

adjusting screw Order-No. 001600 M5x10 DIN 551 for precise length adjustment included in delivery

adjusting screw Order-No. 186017 M5x11,5 for Weeke quick clamping chuck must be ordered separately

clamping elements: combi chuck, quick-change chuck

Diameter 1

5

Axial working depth 1

35

Diameter max

5

Bore / shank diameter

10

Clamping length

10

Total length

70

Number of teeth

2+2

RPM max

8000

Cutting direction

right-handed

Type of feed

MAN - manual feed

Cutting material group

Hardmetal

Machine group

Milling centers

Machine type

CNC stationary manufacturing

Machine / Aggregate

Biesse CNC stationary manuf.

HOLZ-HER CNC stationary manuf.

HOMAG CNC stationary manuf.

IMA CNC stationary manuf.

Nanxing CNC stationary manuf.

SCM CNC stationary manuf.

Felder CNC stationary manuf.

Alberti

Anderson

CMS

Heian

Komo

Maka

Masterwood

Morbidelli CNC stationary manu

Multichem

Reichenbacher Hamuel

Shoda

Weeke CNC stationary manufactu

HOLZ-HER CNC stationary manuf.

HOMAG CNC stationary manuf.

IMA CNC stationary manuf.

Nanxing CNC stationary manuf.

SCM CNC stationary manuf.

Felder CNC stationary manuf.

Alberti

Anderson

CMS

Heian

Komo

Maka

Masterwood

Morbidelli CNC stationary manu

Multichem

Reichenbacher Hamuel

Shoda

Weeke CNC stationary manufactu

Scope of application

CNC machining

Application

Drill

Processing step

Dowel holes

Workpiece material

Wood composite materials

Wood-based panels

Solidwoodandsolidwoodproducts

Wood-based panels

Solidwoodandsolidwoodproducts

Workpiece type

Lightweight panel

Solid wood and veneered mat

Particle boards

Laminated particle board

MDF

Soft wood

Hard wood

Glued laminated timber

Solid wood and veneered mat

Particle boards

Laminated particle board

MDF

Soft wood

Hard wood

Glued laminated timber

Workpiece material

MDF-Polystyrene panel

Blockboard

Honeycomb panel

Plywood

Multiplex

Wood core plywood

OSB particle board flooring

Particle board (raw)

Particle board (CPL-coated)

Particle board (veneered)

Particleboard-highglossfoiled

Spanplatte (HPL beschichtet)

Particle board-melamcoverlay

Twin-wall panel

MDF (raw)

MDF (lacquered)

MDF profiles (coated)

Longitudinal cut wet softwood

Longitudinal cut dry

Cross cut wet

Cross cut dry

BSH

Veneered timber

KVH

Glued laminated timber board

Longitudinal cut wet hardwood

Longitudinal cut dry hardwood

Cross cut wet hardwood

Cross cut try hardwood

Blockboard

Honeycomb panel

Plywood

Multiplex

Wood core plywood

OSB particle board flooring

Particle board (raw)

Particle board (CPL-coated)

Particle board (veneered)

Particleboard-highglossfoiled

Spanplatte (HPL beschichtet)

Particle board-melamcoverlay

Twin-wall panel

MDF (raw)

MDF (lacquered)

MDF profiles (coated)

Longitudinal cut wet softwood

Longitudinal cut dry

Cross cut wet

Cross cut dry

BSH

Veneered timber

KVH

Glued laminated timber board

Longitudinal cut wet hardwood

Longitudinal cut dry hardwood

Cross cut wet hardwood

Cross cut try hardwood