text.skipToContent

text.skipToNavigation

![ZQW]()

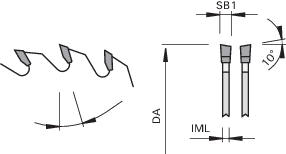

ZQW

ID

58120018

Product variants

Product variants

Product Details

Maschine

table saws

special machines

special machines

Application

for sizing cuts in solid woods

Design

tooth configuration: alternate top bevel "WS"

cutting material: HW TC10/HW TC06

cutting material: HW TC10/HW TC06

Advantages

optimum cutting quality, feed rate and adjustment for material thickness thanks to various numbers of teeth

Notes

larger bore (max. Ø 50 mm) available for a surcharge

Diameter - Outermost cutting point

330

Cutting width 1

3.2

Clamping length

2.2

Bore / shank diameter

30

Number of teeth

24

Tooth configuration

Alternate top bevel

Pin holes

2/7/42 + 2/9,5/46,5 + 2/10/60

RPM max

005800

Cutting direction

universal

Cutting quality

+

Cutting material group

Hardmetal

Cutting material specification [CMSS1]

Board10

Machine group

sawing machines

Machine type

Table and sizing saw-main saw

Scope of application

Machining of solid wood

Application

saw mills / planing mills

Processing step

trimming cut saw/planung mill

Workpiece material

Wood-based panels

Solidwoodandsolidwoodproducts

Solidwoodandsolidwoodproducts

Workpiece type

Solid wood and veneered mat

Particle boards

Soft wood

Hard wood

Particle boards

Soft wood

Hard wood

Workpiece material

Plywood

Wood core plywood

OSB particle board flooring

Longitudinal cut wet softwood

Longitudinal cut dry

Longitudinal cut wet hardwood

Longitudinal cut dry hardwood

Wood core plywood

OSB particle board flooring

Longitudinal cut wet softwood

Longitudinal cut dry

Longitudinal cut wet hardwood

Longitudinal cut dry hardwood